BGA applications have entered the stage of large-scale practical use. No matter consumer electronics, medical security products, or communication equipment, they have a wide range of applications. What follows is the increasing variety and quantity of BGA components. About BGA maintenance, combined with the experience in daily maintenance, let's talk about the frequently encountered problems and their solutions:

1. When blowing and soldering BGA IC, the high temperature will often affect some ICs that are sealed with glue, which often causes other failures ,such as, no boot. What should we do?

When soldering, drop a few drops of water on the IC next to it, and the water will absorb a lot of heat when it is heated and evaporates. As long as the water does not dry, the temperature of the next IC is kept at a safe temperature of about 100 degrees, so that nothing will happen.

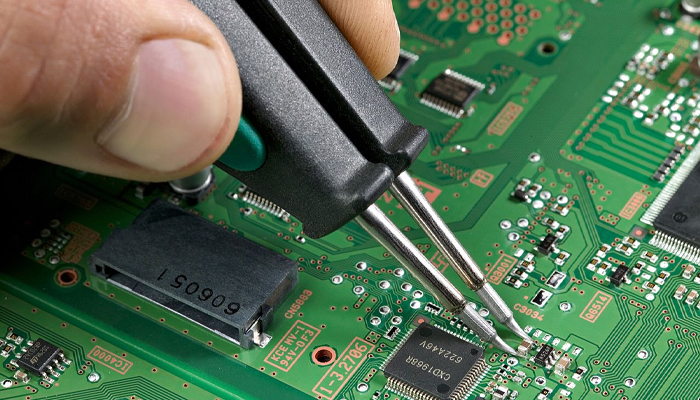

2. How to position the BGA IC during soldering?

For beginners, the line drawing positioning method is more recommended. Before removing the IC, use a pen or a needle to draw a line around the BGA IC, remember the direction, make a mark, and prepare for re-soldering repair. The advantage of this method is accurate and convenient, but the disadvantage is that the lines drawn with the pen are easily washed away, and if the strength of the line drawn with the needle is not mastered well, it is easy to hurt the circuit board.

3. What should we do if there is no tin board when soldering BGA IC?

If not, we can find a way to make a tin planting board. Remove the excess solder from the BGA IC, cover the IC with a piece of white board paper, and repeatedly smear on the white paper with a pencil, so that the solder pin pattern of the IC is printed on the whiteboard paper. Then paste the pattern to a stainless steel sheet of suitable size and thickness, find a drilling tool, and drill holes according to the pattern. In this way, a brand new tin-planting board is made, but for beginners, a tin-planting board is a must.

4. What should I do if the solder balls are too large when tin planting?

If the solder balls emerge from the tin-planting board during the blowing process, resulting in many points not being planted, use a blade (must be sharp) to flatten the protruding part of the tin-planting board. Then fill the unplanted holes with the solder paste, blow it again with an air gun, and when the solder paste melts, stop heating and you will find that the tin spot size is very uniform.

WhatsApp

WhatsApp