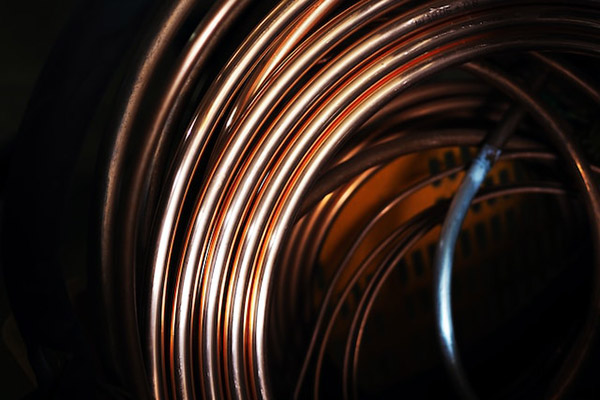

Soldering copper pipe is one of the most common types of plumbing repairs that you'll come across. It's a great way to secure two pieces of copper pipe together, creating a watertight seal with a strong joint. Learning how to correctly solder copper pipe is an essential skill that every plumber should know. Here's everything you need to know about soldering copper pipe.

Soldering copper pipe is a two-step process. First, you must clean the outside of the pipe and the inside of the joint. This will remove any dirt or oxidation that could interfere with the solder adhering to the pipe.

Next, you must preheat the joint with a flame from your torch. This is done to bring the copper up to its melting temperature. Once the copper is up to the correct temperature, you can then apply the solder. The solder should flow around the joint, creating a watertight seal.

Soldering copper pipe requires a few specialized tools. First, you'll need a propane torch with a trigger-operated gas control and a metal nozzle. Next, you'll need a pair of safety glasses to protect your eyes from sparks, and a pair of welding gloves to protect your hands from the flames. Additionally, you'll need a roll of flux-core solder and a soldering rod. Make sure to use the proper size soldering rod for the size of the pipe and joint you're working with.

Once you have all of your tools gathered, its time to start the soldering process. Begin by setting up the torch to the correct heat setting. Make sure that the flame is not too close to the joint or pipe, as this can cause damage to the material. Now, heat the joint until the copper turns a dull red, approximately 600 degrees Fahrenheit. This will be when the copper reaches its melting temperature.

Once the joint is fully preheated, add the solder to the joint. The solder will begin to melt and flow around the joint, securely joining the two pieces of copper together. After the joint is fully soldered, allow it to cool, and then check its integrity with a soapy water test.

Soldering copper pipe can be dangerous if proper safety precautions are not taken. When working with the torch, always keep the flame at least 12 inches away from the joint and pipe. Also, always wear your welding gloves and safety glasses to protect your hands and eyes from sparks. Additionally, make sure that you are working in a well-ventilated area.

Learning how to solder copper pipe is an essential skill for any plumber. With the knowledge of the basics, the right tools, and proper technique, you can easily become a master solderer. Just remember to keep safety in mind at all times, and you'll be on your way to becoming a successful plumber!

WhatsApp

WhatsApp