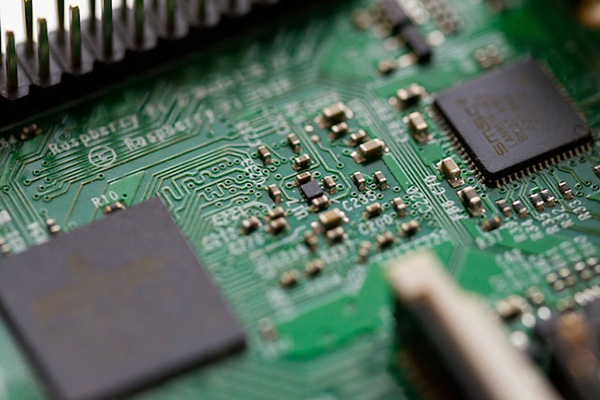

Hand soldering refers to the manual process of joining electronic components together using soldering irons or soldering guns. It involves melting solder, a filler metal, to create permanent connections between the components and the printed circuit board (PCB).

Flexibility: Hand soldering allows for greater flexibility in terms of component placement and adjustments. It is particularly useful for prototyping and low-volume production where designs may change frequently.

Precision: Skilled technicians can achieve high levels of precision with hand soldering. They have fine control over the amount of solder applied and can ensure proper alignment of components.

Accessibility: Hand soldering requires relatively low-cost tools and equipment, making it accessible for small-scale operations or hobbyists. It does not require expensive machinery or complex setup.

Repairability: Hand soldering makes it easier to repair or rework electronic assemblies. If a component needs to be replaced or a connection needs to be fixed, it can be done with hand soldering tools without requiring specialized equipment.

Cost-effectiveness: For low-volume production or one-off projects, hand soldering can be more cost-effective than automated soldering processes. It eliminates the need for expensive machinery and reduces setup time and costs.

Learning and skill development: Hand soldering is a valuable skill that can be learned and honed by technicians, engineers, and hobbyists. It allows for a deeper understanding of the soldering process and the ability to troubleshoot and fix soldering-related issues.

However, it's important to note that hand soldering may not be suitable for high-volume production or components with high pin counts or small surface-mount devices (SMDs) that require precise alignment and controlled heating. In such cases, specialized equipment like soldering rework stations or hot air rework systems may be necessary.

In electronic assembly and repair, several common hand soldering tools are used. Here are some of the essential tools you might find:

Soldering Iron: A soldering iron is the primary tool used for hand soldering. It consists of a heated metal tip that melts solder to create the connections. Soldering irons come in various wattages and tip sizes to suit different soldering tasks.

Soldering Station: A soldering station is a complete setup that includes a soldering iron, a power supply, and temperature control. It provides better temperature regulation and stability compared to standalone soldering irons.

Solder: Solder is a metal alloy with a low melting point that is used to make the electrical and mechanical connections. Common types include lead-based solder (less common due to environmental concerns) and lead-free solder (more widely used today).

Flux: Flux is a chemical compound used to clean and prepare the surfaces to be soldered. It removes oxidation and promotes solder flow, improving the quality and reliability of the solder joint.

Soldering Tips: Soldering iron tips can be interchangeable and come in various shapes and sizes to accommodate different soldering tasks. They can be conical, chisel, or beveled, among other shapes.

Desoldering Tools: Desoldering tools are used to remove solder or components from a circuit board. They include tools like desoldering pumps (also known as solder suckers) to remove excess solder, desoldering wicks or braids to absorb solder, and desoldering irons or soldering guns.

For example, AiXun T320 precision soldering station is the first smart soldering tool that combines the features of integration, intelligent and network in the worldwide. It supports T210 and T245 handles with high compatibility, convenient for use

AiXun smart hot air gun rework station with its ultra-high power heating core, delivers higher wind speed and greater soldering power. The innovative one-key start force working mode allows it to function smoothly even in strong magnetic environments. Experience segment and curve desoldering capabilities, along with customizable desoldering parameters for a personalized soldering experience. Join us and redefine hot air gun technology!

AiXun soldering iron tip is an accessory for soldering station. It can be applied to various scenes, such as glue removing, solder pad cleaning, wire jump soldering, soldering in tiny space, tin planting, pin revise, tin bridge revise, etc. The multi layer alloy electroplating technology contains the advantages of anti oxidize, corrosion resistance and longer service. Also, AiXun offer customize service

4. Other tools

AiXun phone repair tools for mobile phone screen repair and board level repair, when you confuse to select tools and equipment for repair cell phone, we offer the best soldering and desoldering, mobile repair tools for you that developed by experienced repair masters. It is necessary to have effective tools to do good work.Your forever dependable good partner like us.

it's important to note that hand soldering may not be suitable for high-volume production or components with high pin counts or small surface-mount device (SMD) that require precise alignment and controlled heating. In such cases, specialized equipment like soldering rework stations or hot air rework systems may be necessary.

WhatsApp

WhatsApp