A Ball Grid Array (BGA) is a surface mount package used for integrated circuits, commonly found in microprocessors. BGAs offer advantages such as a higher pin count for interconnections compared to dual in-line or flat packs. They allow for mounting on the entire bottom of the device, not just the perimeter, and have shorter leads on average, contributing to better performance at high speeds.

BGA soldering is a method of connecting integrated circuits to a circuit board. Instead of pins, it uses small solder balls arranged in a grid on the underside of the component. This technology allows for high pin density, improved thermal performance, and is commonly assembled using reflow soldering techniques.

BGA soldering boasts several features that make it a preferred choice in the electronics industry:

A. Reduced Package Area: Significantly minimizing the package area, BGAs allow for more compact and efficient electronic devices.

B. Enhanced Functionality: Accommodating a higher pin count facilitates improved interconnection, enabling advanced functionalities in microprocessors and other integrated circuits.

C. Self-Centering PCB Board: The self-centering characteristic during soldering simplifies the tinning process, ensuring precise and reliable connections.

D. High Reliability: BGA soldering is known for its high reliability, providing stable and durable connections critical for electronic devices' performance.

E. Good Electrical Performance and Cost Efficiency: BGAs offer excellent electrical performance while keeping costs in check, making them a cost-effective choice for various applications.

If you want to do good work, you must first sharpen your tools. Good tools can help you do your work better.

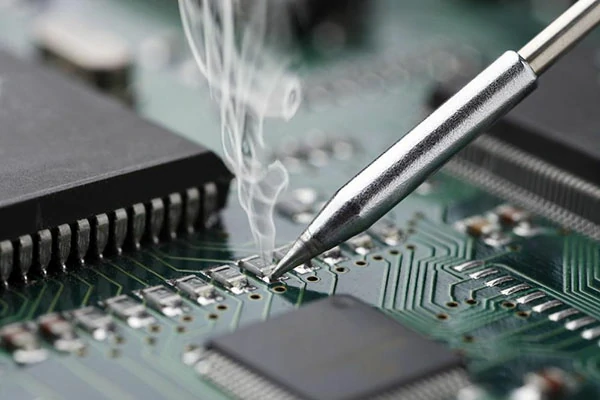

The necessary tools for BGA soldering: hot air gun, constant temperature soldering iron, good flux, tin suction wire (can be replaced by wire), tin paste, PCB cleaner, alcohol, tin planting mesh (steel mesh). The AiXun T3A soldering station is recommended for its intelligence, quick heating, temperature accuracy, and compatibility with various handles.

BGA soldering refers to a form of chip packaging in which the pads are placed on the bottom of the chip.

We use AiXun iheater pro smart desoldering station and AiXun T3A soldering station throughout the BGA repair and maintenance process

Desoldering process:

a. Take out the BGA to be repaired

Before placing the circuit board, be sure to select a suitable pcb template, then gently place the circuit board in the template, fix the circuit board with clips, and adjust the temperature to 180 degrees. You can watch the video below for the tutorial.

b. After taking out the BGA, we clamp the other end of the BGA to be replaced with tweezers and place it on one of the pads.

c. Adjust the position: When soldering the chip, adjust the position and fix it well, and avoid touching the chip with bare hands

d. Adjust the preheating temperature: The adjustment of the temperature is mainly determined by the thickness of the PCB, the indoor temperature, etc. When the indoor temperature is low, it is relatively high. When the PCB is thin, the temperature should be appropriately high.

e. Use flux properly: Whether it is re-soldering or direct repair welding, we need to apply flux first. Please use the special flux for BGA soldering!

f. During the welding process, we need to plant tin balls, and steel mesh can be used to help us quickly plant tin.

Ensuring the quality of BGA soldering joints is crucial for reliable electronic devices. Inspection can be conducted through visual checks and, if available, specialized equipment:

Visual Inspection: Without specialized equipment, visually inspect the outer ring of the chip for consistent solder joint collapse.

Detailed Check: Carefully examine the BGA against direct light exposure to visualize each row of solder balls, ensuring a thorough inspection.

Quality Judgement: For a more precise assessment of internal solder joints, dedicated inspection equipment is recommended to expedite the process and improve accuracy.

As BGA components become smaller, mastering practical BGA soldering methods is crucial for success. The continuous improvement of operational techniques enhances the success rate and reliability of BGA soldering, ensuring optimal performance in electronic devices. If you're diving into BGA soldering, consider the AiXun soldering station as a reliable tool to streamline your workflow and achieve consistent results.

WhatsApp

WhatsApp