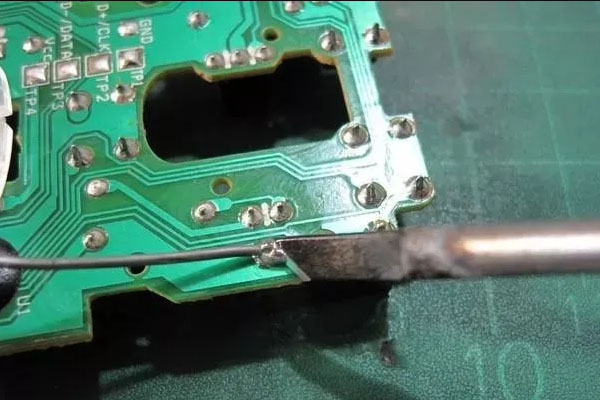

In the maintenance of mobile phones, the components on the circuit board are often replaced, it is requiring the use of high quality soldering tools. Because the components of the mobile phone adopt the surface mount process, the components are small in size, highly integrated, the printed circuit is fine, and the pad is small. If the soldering tools are not selected properly, it is easy to cause faults during the soldering process, such as false soldering, short circuit or even damaged circuit boards. Therefore, it is necessary to use high-end tools as much as possible, such as intelligent temperature controlled soldering station.

The key factor of the iron soldering station easy to use

1. Good heat conduction! The heat energy of the heating components must be quickly directed to the solder joints, so that the soldering can be completed in the shortest possible time. The manuals of many components have soldering time requirements, such as 260 degrees / 5 seconds, if the heat conduction is not good, the soldering iron tip will lose temperature when it touches the solder joint. No matter how high the heating power is, you can only wait for the heat generated by the heating element to transfer slowly, and the soldering time will exceed the standard, then your task will fail in high probability

2. High power!

As we often say, in the face of absolute power, all skills are useless. If there is not enough power support, no matter how good the heat conduction is, it is impossible to quickly increase the temperature of the solder joint.

3. Control temperature!

A soldering iron without temperature control will become red hot when it is continuously powered on, causing the tip of the soldering iron to overheat and not tinned! At this point, the current soldering iron has it.

4. Rapid temperature measurement response ability!

When the soldering iron touches the solder joint, it will lose temperature. The control circuit needs to quickly transfer this process to the power circuit to compensate for the heat required for the temperature rise. The temperature response here is mainly whether the temperature sensing head can directly detect the temperature of the soldering iron tip, rather than the response capability of the circuit

5. Enough heat capacity!

If the heat capacity is too small, the temperature will rise quickly. But since the temperature change itself is a slow quantity, it is impossible to respond to the temperature change too quickly. Enough heat capacity can ensure that the temperature is basically stable in the early stage of the soldering iron tip contacting the solder joint.

If you have a lot of soldering needs or want to improve your soldering experience, it is strongly recommended to start with a soldering station, which is the ultimate evolution of the soldering iron. The temperature adjustment circuit is more complete and precise, the temperature recovery performance is also better, and there are humanized functions such as automatic sleep, waking up. Soldering station is more flexible than other types of soldering iron. You'll never want to use a regular soldering iron again once you've used the soldering station.

96W T3B Intelligent Soldering Station

AiXun T3B soldering station supports T210 and T115 handles, which is specially designed for nano and precise components soldering. It adapts the most advanced and intelligent temperature control system which enables the temperature heating to 380℃ only in 2 seconds, and the temp accuracy deviation is less than 1%. Metal handle base and faster cooling, the soldering iron tip can be changed quickly. Ideal for electronic soldering enthusiasts.

WhatsApp

WhatsApp