At present, many kinds of SMD components are used in the circuit boards of many household appliances and smart tools. In the soldering process, the requirements for soldering technology are also getting higher and higher, including soldering equipment and dimensions, and the requirements for SMD components in manufacturing are also very strict. Although it’s very strict, there are still various mistakes. People has feared of desoldering SMD components. How to desolder?

It is generally not an easy task to remove the SMD. Skills can be mastered through constant practice. Otherwise, it is easy to cause damage to the SMD patch if it is forced to desolder. The mastery of these skills is inseparable from a lot of practice. The desoldering of SMD patches can be roughly divided into three situations:

1. SMD components with fewer SMD pins

It is suitable for SMD components with fewer pins. SMD components with fewer pins include resistors, capacitors, diodes, transistors, etc. Our operation for desoldering this type of SMD is: Firstly tin the PCB, then clamp the component with tweezers on the pad in the middle, and fix it on the circuit board. Solder the pins on the tinned pads with a soldering iron with your right hand. At this time, the left hand can release the tweezers, take the solder wire instead and solder the rest of the pins. The way to desolder SMD components is to take tweezers in your left hand, and use tweezers to clamp one of the components to be desoldered for soldering, then take a soldering iron in your right hand and lightly point it on the pins. At the same time, use tweezers to gently pick up the pins with your left hand. If the pins are loosened, it indicates that the desoldering is successful. Next, repeat this operation to spot-solder and desolder the other pins in turn. Then after the tin has melted, gently lift the part with tweezers.

2. SMD components with more pins

The method is used for SMT components with more pins and SMT components with a long distance. Tin the pad first, then hold the component with tweezers in your left hand and solder one leg, and solder the rest of legs with tin wire. In general, it is best to use a heat gun to desolder these parts. Hold the heat gun in one hand to blow the solder, and the other hand takes out the components with a clip such as tweezers when the solder melts.

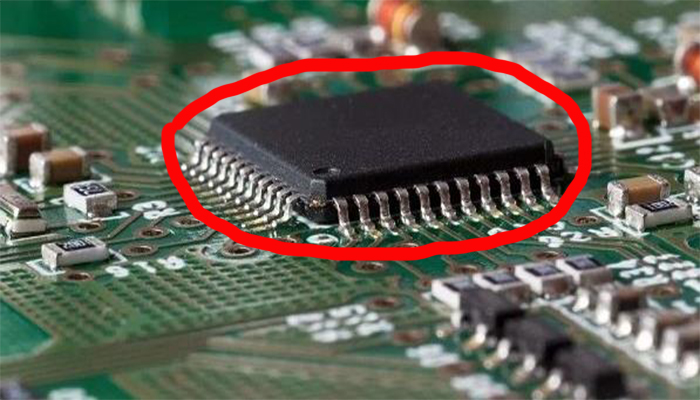

3. SMD components with dense pins

The method is used for the soldering process of components with high pin density, first solder one pin, then fix the pin on the other end with tweezers, and then solder other pins with tin wire. The number of pins is high and dense, and the alignment of pins and pads is the key. Generally, the pads at the corners are plated with small tin. Use tweezers or your hands to align the components with the pads and the edges with the pins. Quietly pressing the components on the PCB, solder the corresponding pins of the pads with a soldering iron. In this process, we will use a magnifying glass, which can assist us in completing the densely packed circuits and pins that cannot be seen clearly.

Desoldering is not a difficult task, but it is more difficult for us to solder and desolder on different circuits and scenarios, because most of the working requires us to understand some theoretical knowledge and certain practice. Only in this way can you get started and try to avoid various errors during desoldering. For the desoldering of SMD mentioned in this article, it requires some knowledge about the circuit board. Only after understanding and operate in practice, you will understand the matters that should be paid attention to when desoldering.

Reading more >>>>>

WhatsApp

WhatsApp