1、Main reason for the corrosion of soldering tips

For electronics and appliance repair enthusiasts, soldering is an integral part of repair work. Soldering tips will get shorter and shorter after being worn and corroded by long-term use. For users, effectively prolonging the service life of soldering tips is undoubtedly an important measure to reduce the production cost. The following is the discussion and solution of AiXun Tech on this problem:

2、Factors Affecting the Life of Soldering Iron Tip

A.How long is the service life of the soldering tip

In the process of repairing electrical equipment, the electric soldering tip is mostly heated without items, so it is easy to oxidize and does not stick to the tin, and the tin surface is easily corroded. The service life of a soldering tip is about 3 months.

B.Factors affecting the life of soldering tip

a) The quality of the solder used for soldering: The quality of the tin material we use during soldering is an important factor affecting the life of the soldering tip. Now the market is relatively chaotic, and you will buy inferior solder accidentally. The inferior solder contains impurities and chemical materials. After heated, a chemical reaction occurs to produce oxides, which accelerates the oxidation of the soldering tip.

b) Soldering temperature: The temperature of the soldering tip during soldering makes it oxidized, which is also a factor affecting the service life.

c) Soldering experience: Beginners and inexperienced soldering personnel often operate in wrong ways. For example, they may not know what the temperature standard is during soldering. Too low or too high temperature will affect the service life of the soldering tip.

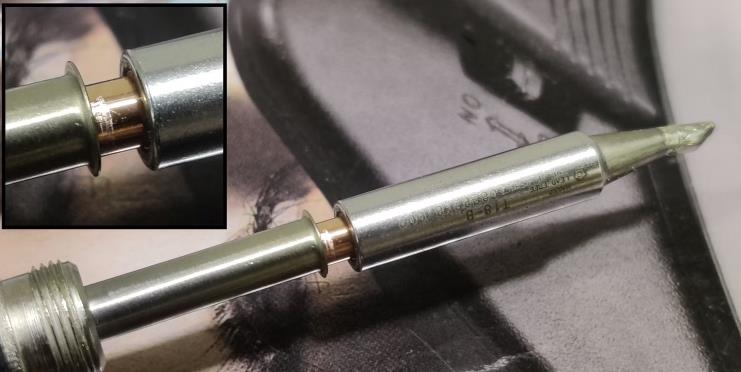

d) Cleaning of the soldering tip: When cleaning the soldering tip, use a file to sharpen the soldering tip by mistake, this operation will make the soldering tip shorter and shorter and shorten its life. Next, let's discuss how to prolong the life of the soldering tip.

3、How to prolong the life of the soldering tip

A、Choose a reasonable temperature. The so-called reasonable is to choose an appropriate temperature in different working environments and for different soldering components.

a) We can choose a relatively low temperature (within the soldering temperature range) when repairing electronic products. In the case of lead-free soldering, we can set the temperature at about 350℃ to meet our soldering conditions, this can protect our soldering tips effectively.

b) In the production line, the general temperature is about 380℃. If soldering relatively intensive components, the temperature should be appropriately increased, around 400℃.

c) If we are soldering larger projects, or the solder joints dissipate heat faster, we can appropriately adjust the temperature to about 450℃.

Therefore, choosing the appropriate soldering temperature for different soldering procedures is also an important measure to protect the soldering tip. In any case, the principle is to choose a lower temperature as much as possible under the premise of satisfying the quality and speed of soldering. This is the main method to effectively prolong the service life of the soldering tip.

B. The correct choice of tin wire.

The tin wire is also an important factor affecting the life of the soldering tip. The acidity and alkalinity of the flux in the tin wire is a problem that most solderers often ignore but confused. The tin wire has strong acidity, good fluidity, and the solder joints are round. This is very popular for solderers, but it is harmful for the soldering tip. The soldering tip and acid are prone to chemical reactions. The copper contained will be exposed to the outside and oxidized. Therefore, the tin wire must be mild, which is beneficial to protect the soldering tip from being oxidized.

C. Cleaning method for soldering tip.

Cleaning sponge (squeeze dry by hand after adding water, and keep the sponge moist), metal cleaning wire, steel ball, silicone pad, and the more common "knock tin" . Different people have different views, choose the right method will help prolong the service life of your tip.

D. Soldering iron working time:

If you are repairing and soldering at home, generally suspend work for more than 1 hour a day, and there is often tin on the tip of the soldering iron.

As the soldering tip is used for a long time, the soldering tip will undergo small-scale deformation and heavy corrosion. When the soldering tip is severely corroded and dirty, you must replace with a new tip to avoid affecting the normal operation of the soldering station.

The above are the solutions that AiXun has summarized to prolong the life of soldering tips. If you have any questions about soldering, please contact us and we will be happy to answer.

WhatsApp

WhatsApp