Soldering circuit board is a method of fixing electronic components on a circuit board and connecting the components to the circuit board through soldering. The following is a detailed description of circuit board soldering, combined with practical methods and techniques:

1. Preparation:

- Collect required tools and materials, including soldering station, soldering tin, soldering wire, flux, tweezers, solder extractor, etc.

- Ensure the work area is well ventilated to prevent breathing harmful fumes.

2. Prepare the circuit board:

- Clean the circuit board surface to make sure it is free of dust, grease or other contaminants.

- Check the pads and pins on the circuit board to make sure they are not damaged or bent.

3. Install components:

- Place components correctly on the circuit board, determining the correct location and orientation based on the circuit diagram or layout diagram.

- Use tweezers or a solder remover to make sure the component is aligned with the pads.

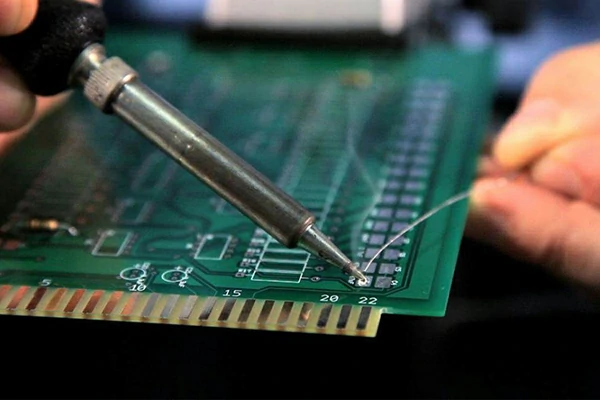

4. Soldering connection:

- Heat the soldering station to the proper operating temperature.

- Use solder to heat the pads and pins to fully melt them.

- Apply an appropriate amount of solder wire to the pads and pins to fully cover the pads and pins.

- Wait for the solder joint to cool down and form a solid soldered connection.

5. Check and fix:

- Check whether the welding points are even, smooth and free of cold welding.

- Check that the solder joints make good contact with the pads and pins.

- Check the soldering points for short circuit or poor contact.

- If necessary, repair the solder joint or re-solder it.

6. Clean and organize:

- Use detergent or alcohol to clean the soldering area to remove flux and other contaminants.

- Organize soldering lines and components to ensure a neat layout of the circuit board.

When soldering circuit boards, you need to pay attention to the following tips and precautions:

- Control the welding temperature and time to avoid overheating or welding for too long to avoid damage to components or circuit boards.

- Use appropriate welding wire and flux to obtain a good welding connection.

- Make sure the solder joints are even, smooth and firm to ensure the reliability of the circuit.

- Frequently inspect and repair solder joints to prevent potential failure or damage.

By following correct soldering methods and techniques, the quality and reliability of circuit board soldering can be ensured, thereby ensuring the normal operation of electronic equipment. When performing welding operations, be sure to follow safe operating procedures to prevent fire or personal injury.

WhatsApp

WhatsApp