Soldering is a process of joining metal parts by melting a low-melting-point metal (solder) to create a bond. It's commonly used in electronics, plumbing, and other fields to make connections between components. The basic how to solder steps involve cleaning the surfaces, applying flux, and heating the joint with a soldering iron until the solder melts and forms a strong connection.

Low-powered (15-40 watt) soldering irons are best for soldering components on circuit boards, while more powerful (60-140 watt) soldering irons work well for joining thicker materials such as braided speaker wire. If you use too powerful an iron on a circuit board, you may damage the component you are trying to connect.

Soldering station is a multipurpose power soldering device designed for electronic components soldering. This type of equipment is mostly used in electronics and electrical engineering. Soldering iron as part of a soldering station. --- From wikipedia

Soldering electronic components, generally used as solder wire is relatively low melting point, it is recommended to use rosin cored solder wire, this type of wire contains rosin flux, very convenient to use for us when soldering.

The new soldering iron head before use, the application of fine sandpaper to the soldering iron head to play bright, energized and hot, dipped in rosin with the soldering iron head edge contact solder wire, so that the soldering iron head evenly coated with a layer of tin (note that to completely cover the entire surface of the iron head), which can facilitate soldering and prevent oxidation on the surface of the iron head.

If the oxidation of the old soldering iron head is serious and blackened, a file can be used to gently grind away the surface oxide to reveal its metallic luster and re-tin it before use.

It is good to have a safe place to put the soldering iron down between soldering sessions. A soldering station will hold the iron securely and provide you with a place to clean the tip of the iron. Some soldering irons come with their own stand. If yours doesn't, you can buy one or make one. A stand is not essential for learning how to solder, but it does help with safety.

Brass sponge - When soldering, the soldering material must be clean and free from contaminants. Some possible contaminants are dirt, grease, oil, rust and oxidation, your tip will oxidize and turn golden brown. This is where the sponge comes into play. Every now and then you should give your tip a good clean by wiping off this build up.

(wire cutters, wire strippers, sharp-nosed pliers and automatic wire strippers)

To facilitate the soldering operation, pointed pliers, offset pliers, tweezers and knives are often used as auxiliary tools and should be learned to use them correctly. Pointed-nose pliers, offset pliers, tweezers, knife.

Soldering tweezers are a great helper at work, they can get into the smallest of circuits and can even be your third best hand when soldering, soldering and desoldering. It's easy to get, and a soldering tweezer can be purchased online for a great deal.

The main purpose of flux is to prevent oxidation of the substrate and filler material during soldering

Most soldering work is carried out on a soldering table equipped with an exhaust fan. It is not a good idea to inhale solder fumes and soldering does produce a lot of fumes. Any type of ventilation/fan you can install will help. This is to prevent inhaling large amounts of fumes which can have a detrimental effect on your body.

During the welding process, the melting of the solder will produce wisps of fumes, when we weld if we do not take safe measures, the fumes will get into the eyes and will irritate them and cause great harm to the eyes, so safety measures are indispensable when welding, so goggles are very important for us when working with soldering.

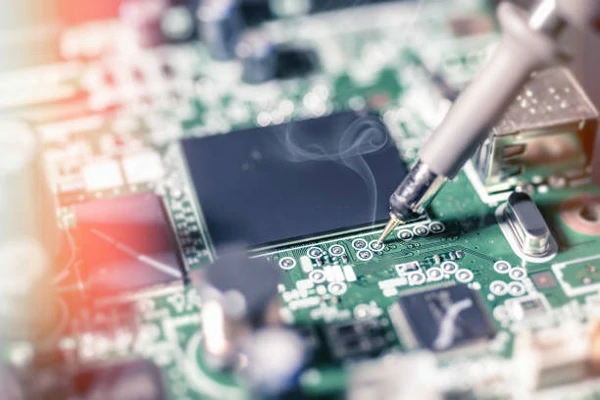

After all the materials are ready, you need to prepare the PCB material you want to solder (repair), and place the material on the soldering table that you think is more comfortable, which will help you to be able to do a better job when soldering.

Let's get into learning how to solder:

1. Precautions before soldering: Before soldering, the component pins or the soldering part of the circuit board should be cleaned before soldering and handling matters to avoid the consequences of unsatisfactory soldering due to dirty soldering parts or impurities, so the clean-up before soldering is very important for the circuit board.

2. Soldering temperature: Set the soldering station temperature to a value sufficient to melt the solder (approx. 400 degrees Fahrenheit). The amount of heat required depends, for example, on the thermal quality of the material and the type of solder.

3. Soldering technique: When soldering leads to a circuit board, you need to heat the metal contacts on the board and the leads themselves. Applying too much heat can damage the board and even your components. In this application the surface of the connection is much smaller than a stranded wire and therefore heats up much faster.

4. Soldering the pcb: The hot soldering iron tip is then applied to the joint between the two surfaces (i.e. the component leads and the PCB surface) and held there for a few seconds before the solder is applied to the joint.

The joint between the two surfaces must be allowed to melt the solder to obtain the desired solder joint, too much heat and time will damage the component and the PCB, not enough heat and time will produce a cold solder joint.

1) The soldering iron plug is best used as a three-pole plug, to make the shell properly grounded.

(2) before use should be carefully checked for damage to the power plug, power cord, and check whether the iron head is loose.

(3) the use of electric soldering iron can not force knocking, to prevent falling, soldering iron head on the solder too much can be wiped off with a cloth, not thrown, to prevent burns.

(4) welding process, the iron can not be placed everywhere, no soldering should be placed on the iron rack, pay attention to the power cord, and you can not ride on the head of the iron, to prevent bad insulation layers and accidents.

5) After use, you should promptly cut off the power supply, unplug the power supply to cool down and then the soldering iron back to the toolbox.

6) It is recommended that you add a layer of tin coating to the tip of the soldering iron when not in use, so that it can be easily coated with tin for the next use, making soldering easier.

Alright, you've got the lowdown on soldering now! Grab your soldering iron, remember those handy tips, and dive into your projects. It's all about practice, so don't be shy. Before you know it, you'll be a soldering whiz, creating cool connections like a pro.

AiXun-The Intelligent & Precision Soldering Expert, provide pro-solutions in soldering field.

WhatsApp

WhatsApp