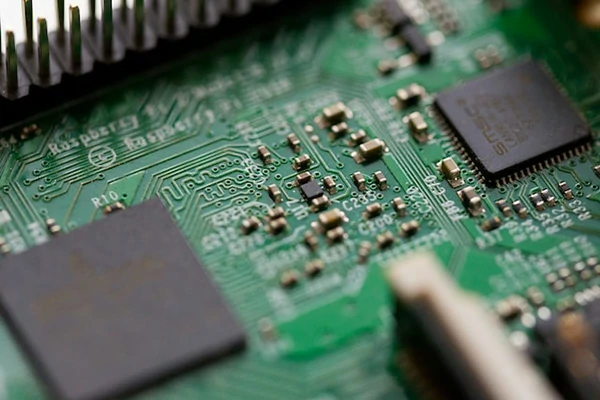

In the world of electronics repair and assembly, reflow soldering plays a vital role in achieving reliable and efficient connections on printed circuit boards (PCBs). While reflow soldering is commonly associated with industrial processes, the use of a rework station can greatly enhance the capabilities and flexibility of this soldering technique. This article explores the versatility of rework stations and their invaluable role in reflow soldering for a wide range of applications.

1. Component Removal and Replacement:

You may curious can a rework station be used for desoldering components? One of the key functionalities of a rework station is the ability to remove and replace surface-mounted components on PCBs. With its integrated hot air gun, the rework station can apply controlled heat to the solder joints, melting the solder and allowing for easy removal of components without causing damage to the surrounding circuitry. This feature is particularly useful in repair scenarios, where faulty or damaged components need to be replaced.

2. Solder Paste Application:

Reflow soldering requires the application of solder paste onto the PCB pads before component placement. A rework station often includes a soldering iron that can be used to precisely apply solder paste to the pads. This ensures accurate and consistent solder connections during the reflow process, contributing to the overall reliability of the assembled PCB.

3. Component Placement and Alignment:

Once the solder paste has been applied, the rework station can aid in component placement and alignment. The soldering iron or hot air gun can be used to gently position the surface-mounted components onto the solder paste. This capability allows for precise alignment, avoiding potential shorts or misalignments that may compromise the functionality of the PCB.

4. Reflow Soldering Process:

The heart of reflow soldering lies in the controlled heating and melting of the solder paste to form robust solder joints. A rework station's hot air gun plays a crucial role in this process. By evenly heating the PCB, the hot air gun ensures that the solder paste reaches its melting temperature, resulting in proper solder flow and excellent electrical connections. The temperature and airflow controls of a rework station enable operators to fine-tune the reflow process, ensuring optimal soldering conditions for various PCB designs and components.

5. Component Repair and Fine-Tuning:

In cases where reflow soldering results in soldering defects or insufficient connections, a rework station provides a valuable solution for component repair. Operators can use the hot air gun or soldering iron to reheat specific areas, allowing for additional soldering or adjustment of component positions. This capability enables precise fine-tuning, ensuring optimal solder joints and mitigating potential reliability issues.

Rework stations are very useful tools for fixing and building electronic devices. They have a soldering iron and a hot air gun combined into one machine. This allows them to do many different tasks. They can remove and replace components, apply solder paste accurately, place components correctly, and heat the solder to create strong connections. While big factories use special machines for soldering, rework stations are great for smaller projects, prototypes, and repairs.

Request hot air rework station quote now

WhatsApp

WhatsApp