SMD soldering (Surface Mount Device) is an essential skill in the world of electronics. As technology continues to advance, SMD components have become the standard in modern electronic devices due to their compact size and increased functionality. This comprehensive guide aims to introduce beginners to the art of SMD soldering, equipping them with the knowledge and techniques needed to excel in this field.

SMD soldering involves attaching components directly onto the surface of a circuit board, eliminating the need for drilled holes. This technique allows for more compact designs, improved electrical performance, and faster assembly processes. The components used in SMD soldering come in various sizes and shapes, making it essential to understand their characteristics to achieve successful soldering.

Moreover, SMD technology has revolutionized the electronics industry by enabling the production of smaller, more lightweight, and feature-rich devices. With the rising demand for innovative gadgets and IoT devices, mastering SMD soldering is a valuable skill for electronics enthusiasts.

Before diving into the soldering process, it is crucial to familiarize yourself with the different types of SMD components. Resistors, capacitors, diodes, and integrated circuits are just a few examples of SMD components used in modern electronics. Each component has unique specifications and plays a specific role in electronic circuits.

Additionally, SMD components come in various package styles, such as 0402, 0805, and QFN, among others. Understanding these package styles is vital as they affect the soldering process and the overall design of the circuit board.

To comprehend the importance of SMD soldering, it is essential to compare it with traditional through-hole technology. Through-hole components require drilling holes in the circuit board for the leads to pass through. While this method was prevalent in the past, SMD technology has replaced it due to several advantages.

SMD components offer higher component density, leading to smaller and more efficient electronic devices. They also exhibit improved electrical performance, reduced signal interference, and enhanced thermal properties. These benefits have driven the widespread adoption of SMD over through-hole technology in modern electronics.

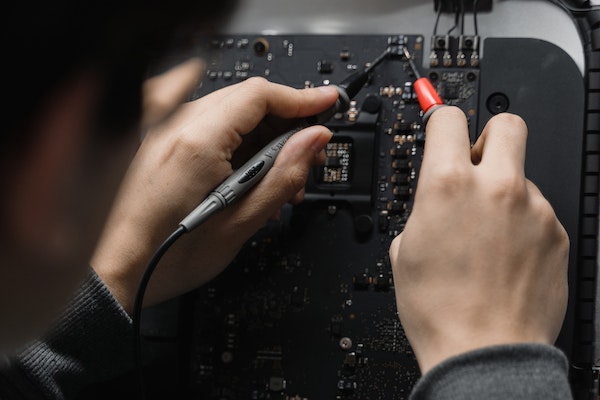

To embark on your SMD soldering journey, you need the right tools and equipment. An SMD soldering station is the heart of your setup, providing precise temperature control and an ergonomic soldering iron for intricate work. Different soldering iron tips are available to suit various SMD package styles, ensuring accurate soldering connections.

In addition to the soldering station, you'll need other essential tools and accessories such as solder wire, flux, and solder wick for proper soldering and rework. Tweezers and magnifying equipment are indispensable for handling and placing tiny SMD components with precision.

Mastering SMD soldering is a gateway to exciting opportunities in the electronics industry. This comprehensive guide has provided beginners with an overview of SMD soldering, its importance in modern electronics, and the essential tools and equipment required to get started.

In the next, let’s get into how to set up Your SMD Soldering Station and the SMD soldering techniques. Don’t forget to add AiXun to your bookmark.

If you want to be AiXun distributor or partner, welcome to contact AiXun to get a quote and start your business right now.

WhatsApp

WhatsApp