Temperature calibration serves as the backbone of precise soldering, a fundamental process in electronics manufacturing and DIY projects. Temperature calibration is the linchpin of ensuring accurate and consistent soldering results. In soldering, the precise application of heat is vital to creating dependable connections between components. Calibrating soldering station temperatures ensures that the displayed temperature corresponds precisely to the actual temperature at the soldering iron's tip.

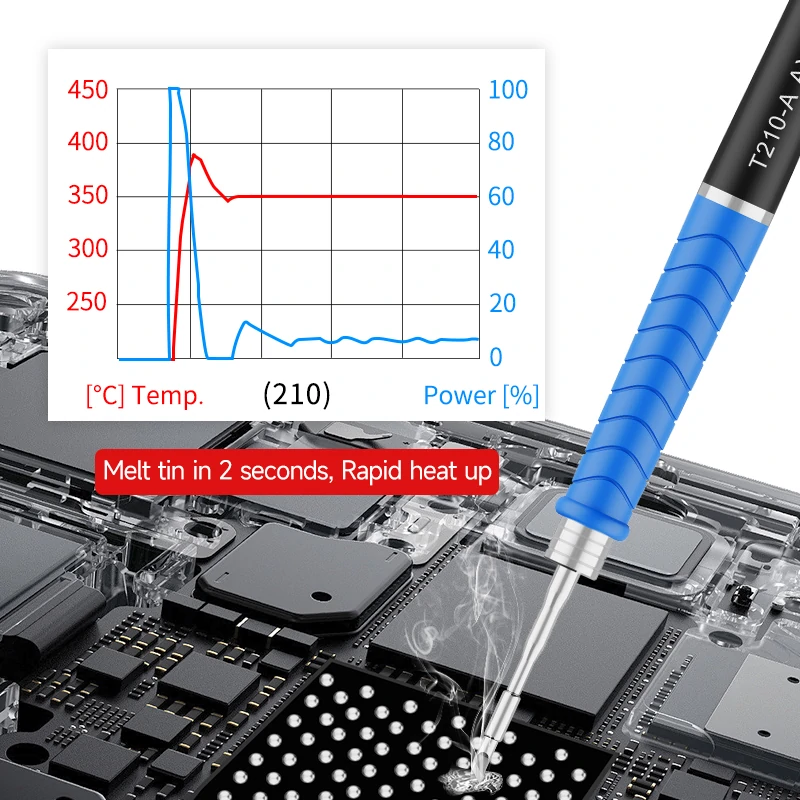

For instance, AiXun's advanced soldering station stands as a testament to temperature control excellence. Known for its stability and intelligent temperature management, the AiXun soldering station boasts an impressive temperature accuracy deviation of less than 1%. This level of precision is essential for achieving flawless solder joints and minimizing the risk of overheating or inadequate connectivity.

Temperature calibration is the linchpin of ensuring accurate and consistent soldering results. In soldering, the precise application of heat is vital to creating dependable connections between components. Calibrating soldering station temperatures ensures that the displayed temperature corresponds precisely to the actual temperature at the soldering iron's tip.

Even minor deviations in soldering temperature can lead to substantial repercussions. If the temperature is too high, components and circuit boards risk overheating and damage. Conversely, if the temperature is too low, you might encounter incomplete solder joints and inadequate connectivity. These issues jeopardize the overall performance, reliability, and safety of electronic devices.

Calibrating your soldering station is an essential practice to maintain precision and uniformity in your soldering endeavors. It's advisable to make temperature calibration a routine procedure, especially considering factors like heating element wear and tear and sensor accuracy.

Warm-Up: Begin by turning on the soldering station and allowing it to warm up for a few minutes.

Temperature Measurement: Use a trustworthy temperature measurement tool, such as a calibrated thermometer or a digital temperature probe, to gauge the actual temperature at the soldering iron's tip.

Comparison: Compare the measured temperature with the temperature displayed on your soldering station. If there's a noticeable discrepancy, calibration is in order.

Adjustment: Most contemporary soldering stations offer calibration adjustments. Follow the manufacturer's instructions to tweak the settings and align the displayed temperature with the actual temperature.

Verification: After adjustments, re-measure the temperature to ensure that it now matches the displayed reading.

Routine Calibration: Perform temperature calibration periodically, especially if you observe inconsistencies in soldering quality or if you frequently utilize the soldering station.

Precise soldering hinges on the accurate calibration of soldering station temperatures. The understanding of why temperature calibration matters and its impact on soldering quality is pivotal for both electronics professionals and enthusiasts. By dedicating time to calibrate and uphold the temperature accuracy of your soldering station, you pave the way for consistent, reliable, and superior soldering results that withstand the test of time.

WhatsApp

WhatsApp