Solder paste, solder wire and tin bar are all essential materials in the soldering process, each playing an important role in their respective fields and there is no substitute for them. Lets check Solder paste vs. Solder wire vs. Tin bar.

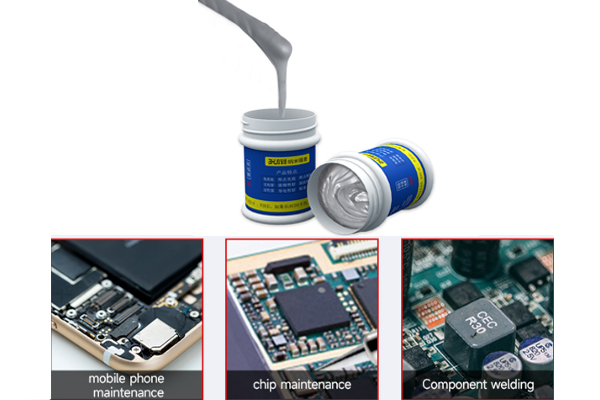

Solder paste is a type of soldering flux that comes in a semi-solid form. It is applied to the surface of the metal using a brush or applicator and helps to improve the flow of the solder and promote a strong bond between the metal surfaces. Solder paste is commonly used in surface mount technology (SMT) and other forms of microelectronics soldering.

Solder wire is a type of solder that appears as a thin, flexible strip of metal. It is typically used to join and make electrical connections between metal parts and printed circuit boards (PCBs). Solder wire can be used alone or in conjunction with solder paste, a substance that contains flux, a chemical that helps to remove oxidation from metals during soldering.

Tin bar is a solder alloy cast or extruded into bar form for melting in solder pots. The most common alloy for soldering electronic assemblies contains 63% tin, 37% lead and has a melting point of only 361°F.

Solder paste is generally wettable and contains flux components that can isolate the air to prevent oxidation. There are two types of solder paste, leaded and lead-free, which are mainly used in SMT, hot air and laser soldering;

Solder wires generally do not contain flux, and different types of tin wires have different fluxes. It is mainly used for soldering iron, laser soldering, etc. It is particularly suitable for heating while feeding tin. It should be noted that tin wire without additives cannot be used directly for soldering electronic components, because it has no wettability and expansion, and soldering will produce spatter and solder joints are not well formed.

Tin rods can be divided into leaded and unleaded tin rods. They are generally used for dip soldering, DIP and wave soldering. They have good wettability, good flowability, easy tinning, bright and full solder joints and oxidation resistance. strong characteristics. As the tin bar is made of pure tin, there is less tin dross, which can improve the utilisation rate;

Today, solder paste, tin bars and tin wires are widely used in SMT, communication equipment, computers and other electronic equipment, whether spot soldering, wave soldering, reflow soldering or printing, ranging from major brands of electronic equipment factories to small We can all see them in mobile phone repair shops. They are the most widely used soldering consumables on the market today. It is believed that in the future development, solder paste, tin bars and tin wires will also be used in more soldering operations of electronic devices.

Above is the content of solder paste, solder wire and tin bar introduced by AiXun, I hope it will be helpful to you. For more solder paste information and prices, please click on AiXun official website for consultation.

WhatsApp

WhatsApp