1. AiXun Intelligent Precision Soldering reminds everyone that after getting the bare PCB board, you should first conduct a visual inspection to see if there are problems such as short circuit and open circuit. Then familiarize themselves with the schematic diagram of the development board, and compare the schematic diagram with the PCB silk screen layer, to avoid it does not match the PCB.

2. After the materials required for PCB soldering are prepared, the components should be classified, and all components can be divided into several categories according to the size, which is convenient for subsequent soldering. A complete bill of materials needs to be printed. During the soldering process, if one item is not soldered, use a pen to cross out the corresponding option, which is convenient for subsequent operations.

Before soldering, anti-static measures such as wearing an electrostatic ring should be taken to avoid damage to components caused by static electricity. After the equipment required for soldering is ready, the tip of the soldering iron should be kept clean and tidy. It is recommended to use a soldering iron with a flat angle for the initial soldering. When soldering components such as 0603 package components, the soldering iron can better contact the pad and facilitate soldering.

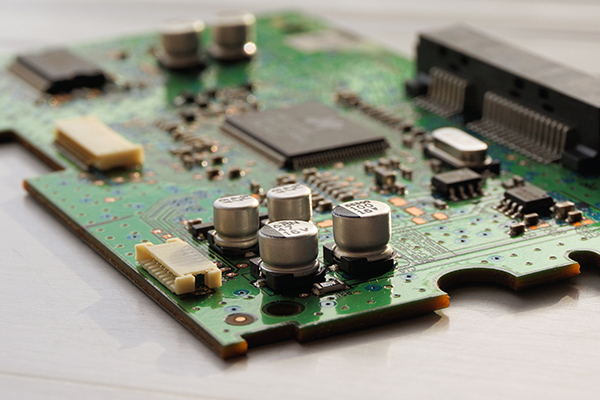

3. Components should be selected for soldering in the order of components from low to high and from small to large. In order to avoid the inconvenience of soldering larger components to the soldering of smaller components. Prioritize soldering integrated circuit chips.

4. Before soldering the integrated circuit chip, it is necessary to ensure that the chip placement direction is correct. For the chip silk screen layer, the general rectangular pad indicates the starting pin. When soldering, one pin of the chip should be fixed first, and then the diagonal pins of the chip should be fixed after fine-tuning the position of the components, so that the components are accurately connected to the position and then soldered.

6. SMD ceramic capacitors and Zener diodes in voltage regulator circuits have no positive and negative poles. Light-emitting diodes, tantalum capacitors, and electrolytic capacitors need to distinguish positive and negative poles. For capacitors and diode components, generally the marked end should be negative. In the packaging of SMD LED, the direction along the lamp is the positive-negative direction. For the packaged components with the diode circuit diagram marked by silk screen printing, the negative terminal of the diode should be placed at the end with the vertical line.

7. For crystal oscillators, passive crystal oscillators generally only have two pins, and there is no distinction between positive and negative. Active crystal oscillators generally have four pins. Pay attention to the definition of each pin to avoid soldering errors.

8. For the soldering of plug-in components, such as related components of the power module, the pins of the device can be modified before soldering. After the components are placed and fixed, the solder is usually melted with a soldering iron on the back and then integrated into the front by the pad. There is no need to put too much solder, but the components should be stable first.

During the soldering process, the PCB design problems found should be recorded in time. For example, installation interference, incorrect pad size design, wrong component packaging, etc., for subsequent improvement.

10. After the soldering is completed, use a magnifier to check the solder joints, and check whether there are false solders and short circuits.

11. After the PCB soldering work is completed, the surface of the PCB should be cleaned with alcohol and other cleaning agents to prevent the iron filings attached to the surface of the PCB from short-circuiting the circuit, and make the PCB cleaner and more beautiful.

The above are the precautions for PCB soldering shared by AiXun Smart Precision Soldering. Follow AiXun , we will update every day!

WhatsApp

WhatsApp