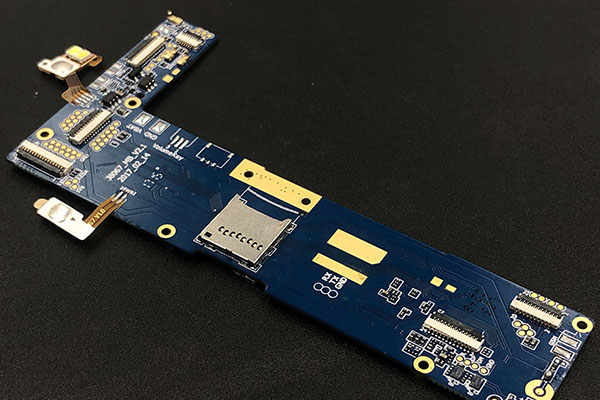

In mobile phones, laptops, cameras and other digital products, a large number of flexible cables are used for signal transmission. The surface layer of this type of flexible cable is a plastic film with high toughness, and many thin metal strips are arranged in the middle. AiXun precision soldering will talk to you today about the processing method of FPC flexible cable and some technical points. Because some flexible cables are in the position of frequent flipping, they are prone to breakage after a long time. If there is no new cable to replace, the following methods can be used for emergency treatment.

Step 1: Find the crack point

First observe the structure of both ends of the cable and the fixing method of the plug, then carefully separate the plug of the flexible cable from the motherboard, and gently pull out the cable. In this step, you must observe carefully first to determine the removal method, and do not do it rashly to prevent serious damage to the flexible cable or plug.

Next, first use the observation method to find the breakpoint. That is, use the naked eye to see where there is an obvious fold in the cable. Breaks are always caused by creases. If it is difficult to see with the naked eye, you can use a high-power magnifying glass and place the flexible cable under strong light to find it. Since most flexible cables are relatively thin, the breaking point can generally be clearly seen under strong light. In order to ensure that the breakpoint you are looking for is accurate, you can use a digital multimeter to "diagnose" at this time. Since the tip of the ordinary multimeter pen is too thick, it is recommended to fix a sewing needle on the pen tip and set the multimeter to the resistance 200Ω range.

Step 2: Handle breakpoints. After finding the breakpoint, use a blade to gently scrape off the film on the surface of the breakpoint. Since the flexible cable is too thin , you must be careful in this step, and the force must be moderate. The metallic luster of the wire shall prevail. The thin cable cannot be broken, let alone scratch a hole in the cable.

Step Three: Soldering. First use a blade to scrape a little rosin powder and sprinkle it on the scratched cable, and then wait for the temperature of the soldering iron to be normal, unplug the power plug of the soldering iron (this step is to prevent the static electricity of the ordinary soldering iron from damaging the motherboard), use the residual heat, Put a little solder on the soldering iron tip, then quickly solder the breakpoint.

In this step, the soldering time must be short, otherwise it is easy to burn the cable. If the soldering fails once, it can be repeated several times until it is connected with a multimeter.

Step Four: Reinforcement. After the breakpoint is soldered, apply a layer of 703 silicone rubber evenly on the front and back of the solder joint and the crease. Wait for the 703 silicone rubber to dry naturally (about one or two hours), and then apply 703 silicone rubber one or two times, and wait until the silicone rubber is completely dry again before installing it for testing.

Since 703 silicone rubber is elastic after air drying, this treatment can not only fix the solder joints, but also protect the flexible cable at the crease and prevent it from being disconnected again.

The above is the emergency treatment method for FPC soft cable breakage. If you have any questions or ideas, feel free to contact AiXun.

WhatsApp

WhatsApp