I have collected some soldering iron tips recently, and I feel that many people should not know that different soldering iron tips have different uses, because when we solder what kind of products, we often only use one or two fixed soldering iron tips, so we only remember the shape of three soldering iron tips at most in our minds.

Although we only use two different types of soldering irons, it is important to be familiar with and understand the purpose of other types of soldering irons.

We take AiXun's Soldering Iron Tip Kit as an example for soldering tips:

This is what many people new to soldering might consider to be the only type of soldering iron tip because it looks like a soldering iron tip rather than being ground flat on one side.

Thanks to its round shape, it can be welded from any angle and you can use this special tip in a wide range of welding applications from spot welding to drag welding. Because of this, thin tips are widely used for general-purpose soldering, but are often set aside when specific soldering jobs need to be done

These tips, which look like chisels, are more popular and widely used for general-purpose soldering, just like the A-series tips. The difference is that these tips provide a much larger surface area on the face and tip of the chisel than the A-Series tips.

Because the B-series tip has a larger contact area, more heat can be transferred from the iron to the electrical components and/or solder. With more heat transfer, the solder will flow more easily, arguably making the B-series tips easier to use for quick soldering applications than the A-series.

But with soldering iron tips like this series, you can't choose too big, because larger tips are not always better, even if you use larger tips there will be more heat transfer. The reason for this is that if your tip is too large, you could end up causing solder to flow from where you're trying to work to a friend next to it, creating a solder bridge that's going to cause us trouble.

Although they look like they were accidentally ground flat on one side, these C-Series tips are very useful, especially when drag soldering. The slightly curved surface is ideal for spreading solder over the tip and then applying a small amount of solder evenly to multiple components in close proximity (such as pins on surface mount components).

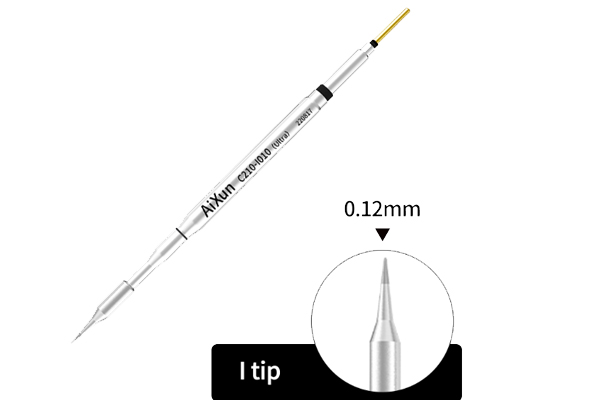

The I series tips are for needle point work. The downside of being able to do detailed work, however, it is difficult to solder (relatively) larger components due to the small tip (and therefore less surface area) that cannot transfer a lot of heat.

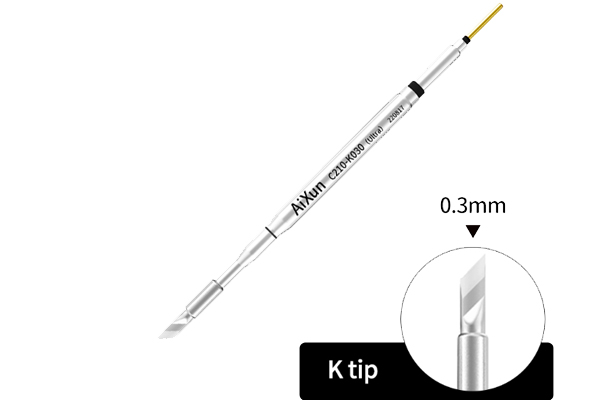

This special type of soldering iron tip can be used for a variety of applications. The angled cutting edge (K for knife) allows spot welding, drag welding and fixed welding bridges. However, since it's so wide, spot soldering in tight areas can get a little unwieldy, though not impossible.

The above soldering iron tips are only the parts we know about. There are more types of soldering iron tips waiting for us to understand. No matter which kind of soldering iron has its own advantages, it also has its own shortcomings. But we need to know that there are a variety of techniques that can be used to accomplish countless welding jobs.

Of course, we can choose a soldering iron tip to complete all the work of soldering during the soldering process. But it might be easier to use a different tip that is better suited for the job, but in the end it's up to you.

If you have any questions or comments, please feel free to contact us and we will get back to you as soon as possible.

WhatsApp

WhatsApp