SMT soldering technology has been widely used in the electronics industry at present, and it is an indispensable installation technology to realize the miniaturization and high integration of electronic products.

Matters needing attention when soldering SMT chips

a. Generally, the time of the whole soldering operation of the solder joint is controlled within 2~3s.

b. The time between each soldering step is very important to ensure the soldering quality, and it needs to be mastered gradually through practical operation.

c. After the soldering operation is completed, the position of the welded part cannot be changed until the solder paste is completely solidified.

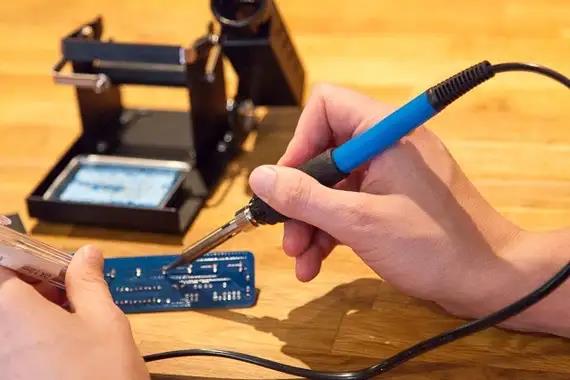

d. The electric soldering iron should generally be an internal heating type (20~35W) or a constant temperature type, and the temperature should not exceed 300℃. Generally, a small conical soldering iron tip is used.

e. The pad holes should also be wetted and filled when soldering more than two layers of printed circuit boards.

f. After soldering, the excess pins should be cut off, and the printed circuit board should be cleaned with a cleaning solution.

g. The soldering time should be as short as possible, generally no more than 3s.

h. It is best to use an electric soldering iron with a constant temperature of 230 degrees.

i. The workbench should preferably be treated with anti-static.

j. Use a soldering iron tip with a narrower tip, so that it will not touch the adjacent endpoints when soldering.

Precautions for the use of solder paste for SMT patch:

1. Storage temperature: It is recommended that the best temperature for storage in the refrigerator is 5-10°C, and should not be lower than 0°C.

2. Do not store the solder paste in the refrigerator for too long.

3. Storage requirements: Take out the solder paste from the freezer and thaw it naturally for at least 4 hours. Do not open the bottle cap when thawing.

4. Used old solder paste: It is recommended to use up the solder paste within 12 hours after opening. If you need to save it, please use a clean empty bottle, then seal it and put it back in the refrigerator for storage.

As for the precautions for the SMT soldering process, that all for here. There are many operation processes in the SMT patch process, involving many process technologies, not only the above points, but these require operators to learn and understand in depth, master the key points to avoid mistakes.

WhatsApp

WhatsApp