Welcome to the world of soldering! This guide will equip you with the knowledge and techniques you need to join metals like a pro. Whether you're a curious beginner or an experienced hobbyist looking to refine your skills, this comprehensive resource has got you covered.

What is Soldering?

Soldering is the process of joining different metals by melting a special metal alloy called solder. This alloy, typically made of tin and lead, is melted using a hot iron, creating a strong and permanent connection between the metals.

How Does Soldering Work?

The magic of soldering lies in the use of a soldering iron. This tool, connected to a temperature controller, heats the solder to its melting point. The molten solder then flows into the joint between the metals, solidifying upon cooling to form a solid bond. If needed, a desoldering tool can be used to remove unwanted solder.

Types of Soldering

There are three main types of soldering, each with different temperature ranges:

- Soft soldering (90°C - 450°C): This method uses solder with a low melting point, making it ideal for delicate components. However, it's not suitable for high-temperature applications.

- Hard (silver) soldering (>450°C): This process uses silver or brass alloys, requiring a higher temperature often achieved with a blowtorch.

- Brazing (>450°C): Brazing involves heating the metals being joined without melting them. Solder is then placed between the heated metals, melting and acting as an adhesive.

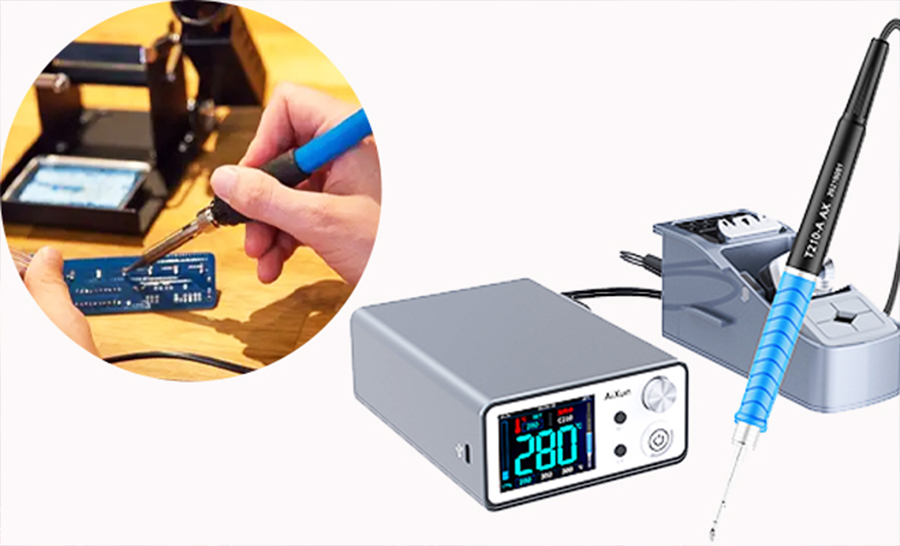

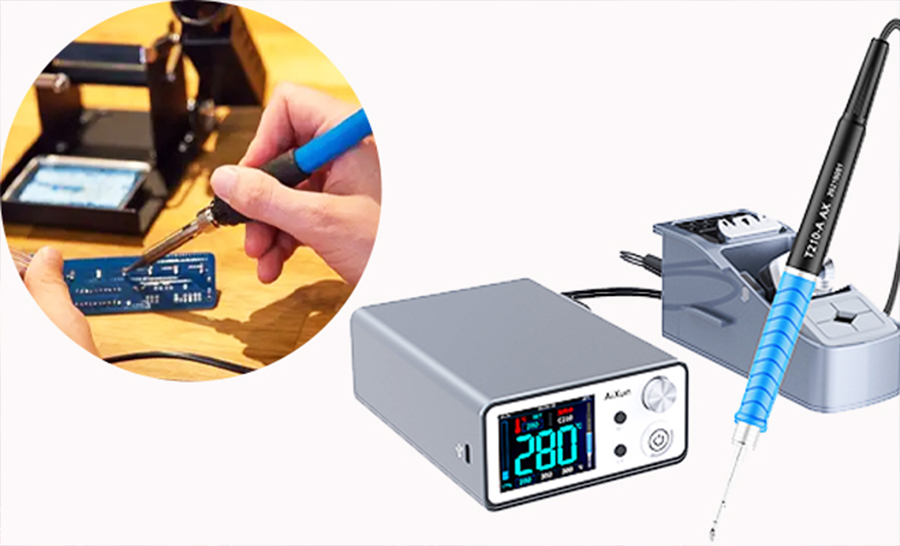

Essential Tools and Materials

To embark on your soldering journey, you'll need these essential tools and materials:

- Soldering station: This provides power and temperature control for your soldering iron.

- Soldering iron: This tool heats the solder and melts it onto the joint.

- Tweezers: These help you hold small components and wires during soldering.

- Cleaning sponge: This keeps your soldering iron tip clean for optimal heat transfer.

- Spare soldering iron tip: Having a backup tip ensures you can continue soldering even if the current tip gets worn out.

- Flux: This helps prevent oxidation and improves the flow of solder during the process.

Step-by-Step Soldering Guide

Follow these steps for a successful soldering experience:

- Turn on the soldering station and wait for it to reach the desired temperature.

- Tin the soldering pad by applying a small amount of solder to the component's soldering points.

- Hold the component with tweezers and solder the remaining pins using tin wire.

- Gently press the soldering iron's tip against the joint, then remove it and allow the joint to cool.

- Inspect the soldered joint to ensure it has a smooth, spherical interface and a bright appearance. If necessary, rework any dark or faulty joints.

- After completing the soldering, turn off the power, let the soldering iron cool, and unplug it.

Tips for Soldering Electronic Products

If you're new to soldering, practice on scrapped circuit boards to improve your skills. Watching soldering videos can also be a valuable learning resource. Remember, our soldering engineers are always available to answer your questions and provide expert guidance.

Conclusion

Soldering is a valuable skill for various tasks, from repairing electronics to creating jewelry. By understanding the principles of soldering and following this step-by-step guide, you can confidently tackle your soldering projects and achieve professional results. Remember, practice makes perfect, so keep honing your skills and enjoy the art of soldering!

WhatsApp

WhatsApp