The full name of BGA is "ball grid array". It is to blow the solder balls on the CPU contacts with a hot air gun through the ball planting board, and then align them with the main board PCB for heating and soldering. This form is widely used in notebooks and all-in-one motherboards with embedded CPU.

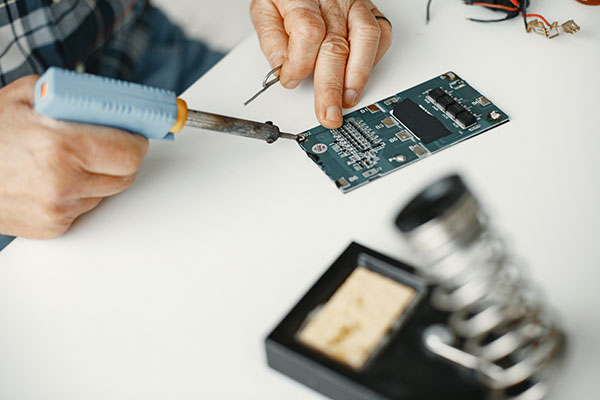

The purpose of BGA chip ball planting is to facilitate the soldering of BGA chip. BGA technology is used more and more widely, and it is inevitable to encounter the problem of re-soldering BGA chips. Generally, the north-south bridge of the motherboard or the chip with the contacts under the chip has a problem of desoldering. Generally, BGA equipment can be used for soldering. Only when soldering is invalid, the ball will be planted. Ball planting is a job that tests patience.

AiXun Precision Soldering will introduce two ball planting methods for you;

One: "solder paste" + "solder ball"

This is recognized as the best and most standard ball planting method. The ball planted by this method has good weldability and good gloss. The ball will not run away during the solder melting process, and easier to control and hold.

Two: "soldering paste" + "solder ball"

Simply speaking, this method is to replace the role of solder paste with solder flux. However, the characteristics of the flux are very different from those of the solder paste. The solder paste will become liquid when the temperature rises, which will easily cause the solder balls to run around; moreover, the solderability of the flux is poor, so it is said to use the first method is ideal for ball planting. Of course, both of these methods require special tools such as ball planting seats to complete.

Second: The key point is here. Use a small flat-tip brush to gently apply a layer of flux on the BGA pad. The flux must be evenly applied. How to judge it? Here is a little trick: after painting, look at the reflection under the fluorescent lamp to see that the traces of oil should be even, not more on one side and less on the other. This step is very critical. If it is not done well, there may be problems whether it is heated with a stencil or without a stencil, especially if the flux is not evenly applied without a stencil, and the solder balls may be connected together when heated.

Third: Put the chip on the base of the ball planting table, then cover the stencil evenly and pour suitable solder balls into it, shake it gently to make every hole of the stencil covered with solder balls, and then remove the stencil away. Then clamp the chip to the heating table to melt the solder ball. (When melting solder balls, pay attention to distinguishing the temperature of lead and lead-free. Generally, 190 degrees is used for lead and 240 degrees for lead-free). The BGA solder balls will melt quickly when heated in this way, otherwise it will not melt for a long time and will easily damage the chip.

Fourth: What is considered to be heated well? Years of experience shows that when the tin ball melts, the color will turn gray and then shine in a liquid state, that's it! Therefore, when heating, there must be a place with good light, preferably under a fluorescent lamp, so that it can be seen more clearly (Note: the middle of the BGA is generally slower than the surrounding heat, so we see the tin ball in the middle turn gray and shine, then stop heating), but this method is difficult for novices. If the BGA is less, it is hard to distinguish with the naked eye. But don’t worry, another way is to gently touch it with the tip of tweezers during the heating process. If the tin ball melts, it will become liquid and deformed. Of course, it will be displaced when it is not melted. If it is difficult to melt the tin because the chip is too thick, you can use a heat gun to heat it at a fixed height, and keep rotating it. Then the solder ball in the middle of the BGA will light up and stop heating immediately. Let it cool naturally, then success!

Stencil: Make sure that the stencil is not deformed, and it must be cleaned. If it is deformed, correct it by hand. If the deformation is too serious, replace a new one.

Selection of solder balls: The specifications of solder balls on the market are 0.2mm 0.25mm 0.3mm 0.35mm 0.4mm 0.45mm 0.5mm 0.6mm. When selecting, you must choose clean, uniform solder balls, and distinguish lead-free tin ball, since the melting temperature will be different.

WhatsApp

WhatsApp